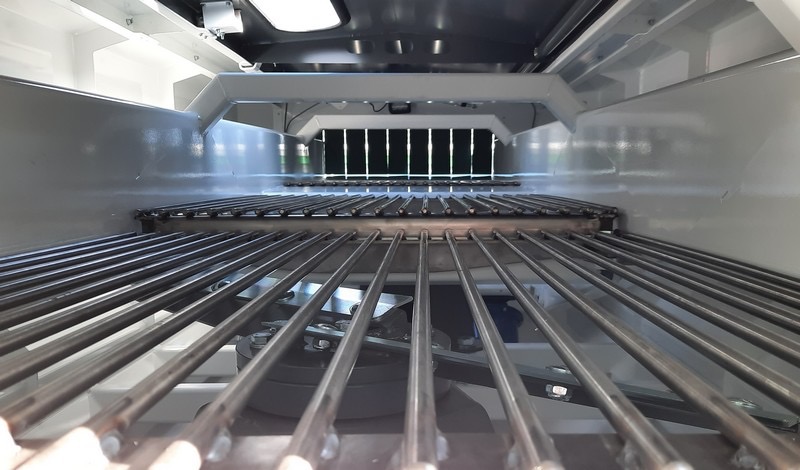

TumbleJet crate washer

Hygiene on arable farms is becoming increasingly important. Farmers recognise that washing crates is part of hygienic and professional work. Keeping the boxes clean also prevents disease, resulting in lower failure rates. The TumbleJet crate washer offers the solution for easy cleaning of heavily soiled cubic crates, as adhering soil is a major potential source of contamination. Not only in (seed) potatoes but also in carrots, chicory roots, celeriac, onions and flower bulbs, among others.

- Prevents contamination of products

- Suitable for different box sizes

- Lower production costs (less wastage due to diseases)

- Longer box life

- Cleaning certificate (Global GAP)

The TumbleJet is available in 2 different variants, namely;

SOLO

- 10 to 25 crates/hour

- Water consumption; 3 to 7 m³/hour

- Power connection; 20A 3 phase + N

- Equipped with touchscreen and remote control

DUO

- 25 to 50 crates/hour

- Water consumption; 7 to 10 m³/hour

- Power connection; 25A 3 phase + N

- Equipped with touchscreen and remote control

Ruijter Machines crate washer

Ruijter Machines’ crate washer washes your crates quickly and powerfully. Through simple and well thought-out techniques, the machine is very maintenance-friendly and can be easily and safely operated by anyone.

Advantages:

- Simple operation

- Low maintenance

- Washing time inside and outside separately adjustable

- Use of a double fork carriage is possible

- Easy to operate by remote control

With the box washing machines of Ruijter Machines, a lot of options are possible to create a crate washer according to your own wishes. Contact us for the possibilities!

Okura robotic arm palletizing technology

Okura’s robotic arm is fully automated and thus a solution for the future. The robot arm can achieve greater efficiency through high speed, high quality and high power due to its wide working range and high payload.

Specifications:

- Accurate and flexible

- Unmatched speed

- User-friendly

- Offline stacking programs

- Rotation angle of 360 degrees

Holoras onion topper

The Holoras onion topper is specially designed for topping onions and flower bulbs. The high speed and the special shape of the blades create a strong air flow. This airflow sucks the onion tails between the bars of the vibrating screen, after which they are cut off by the sharp knives just under the screen.

All versions are available with closed air circulation and discharge conveyor. The trimmers are equipped with internal lighting and come standard with an automatic switch box. The standard screen drop size is 28 mm.

Options:

- Variable frequency controlled vibrating or knife motors

- Separate control cabinet

- Various screen sizes

- Extension discharge belt

- Remote control

- Damping infeed

- Preparation for extraction

Doornbos mechanical clod separator

Doornbos’ mechanical clod separator offers quality, carefully separating your product from clods.

For more information, please contact us.

Tomra electronic clod seperator

The Tomra electronic clod separator is effective in separating clods and e.g. potatoes. This machine is very efficient and easy to use. It is also easy to move and easy to maintain.

Specifications:

- Fast and effective

- Removes foreign materials (stones, clods, etc.)

- Robust and reliable

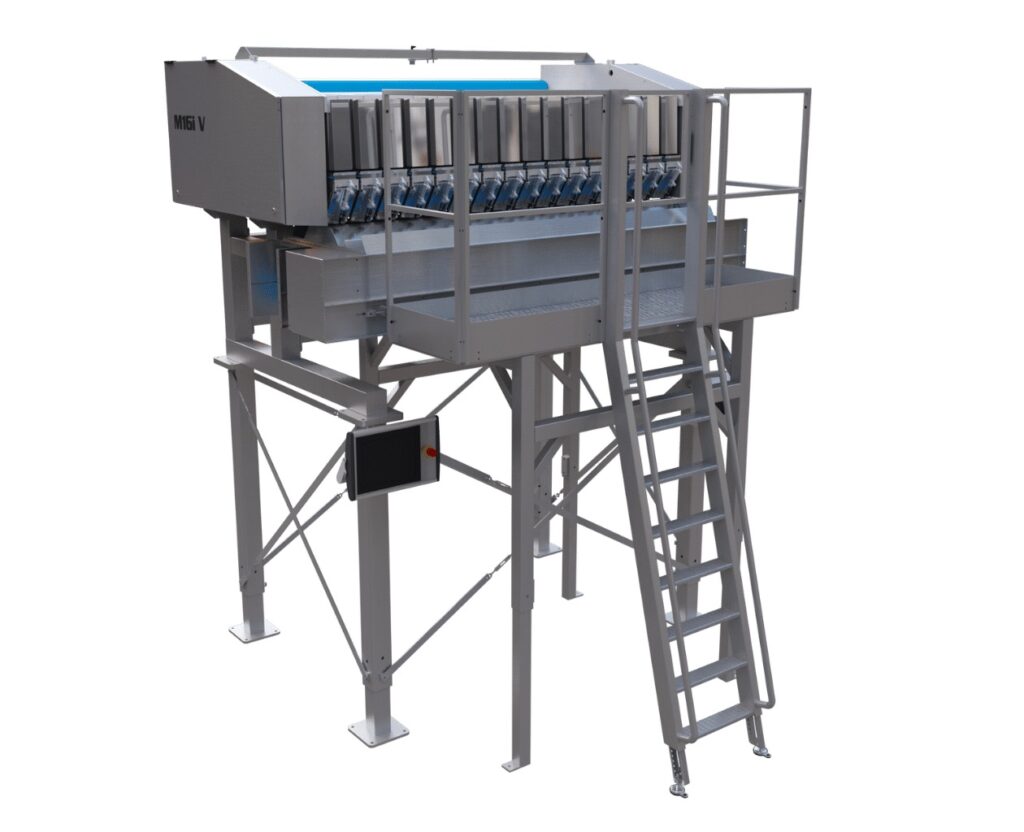

Manter weighing machine

Manter offers a wide range of different weighers, so there is a suitable machine for everyone! Contact us to discuss the many possibilities and options.

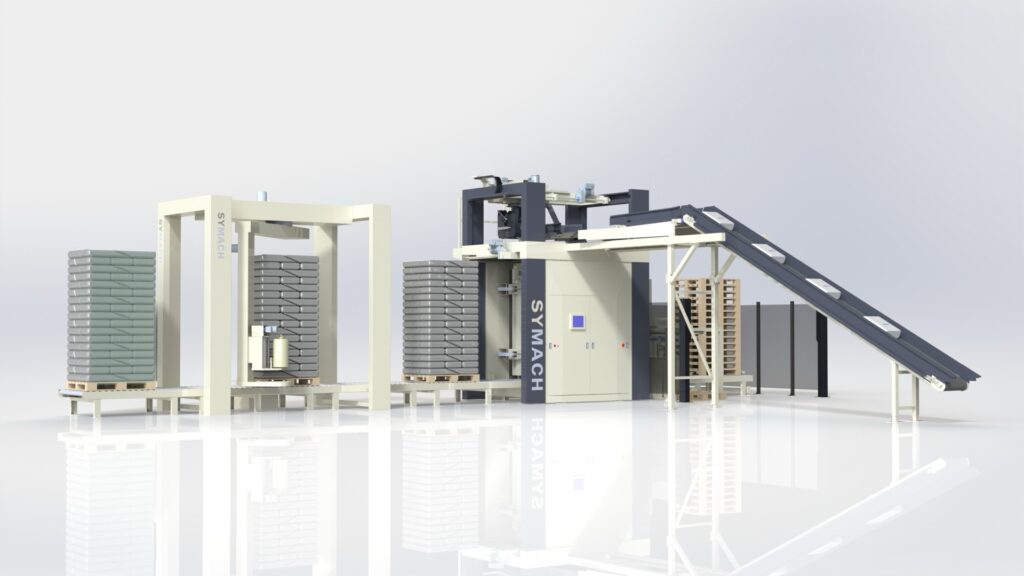

Symach palletizer

Symach’s palletizer is standard extremely suitable for palletizing bags. They can also stack overlapping. If desired, the machine can be expanded with the optional Hybrid Multi palletizing head to palletize boxes, crates or bundles. Whatever option you choose, the machine remains quickly and intuitively changeable.

Typical of Symach’s palletizers is the way it stacks bags, within the dimensions of the pallet. So no products coming over the pallet edge. This greatly reduces the risk of damage to your product. It also allows the pallets to be loaded efficiently.

Specifications:

- Intuitive drag and drop operation

- Product-friendly handling

- Overlapping of bags

- Perfectly straight stacking

- High efficiency

- Low maintenance

Would you like more information about the above machines or are you curious?

Contact us or fill out the contact form below and we will get back to you as soon as possible!